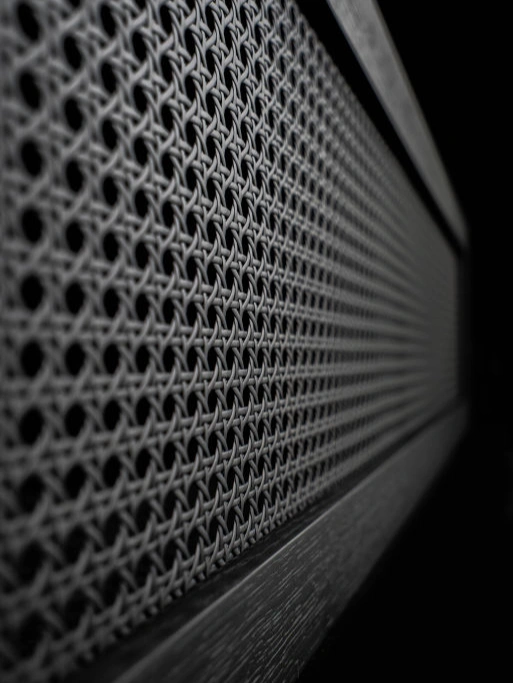

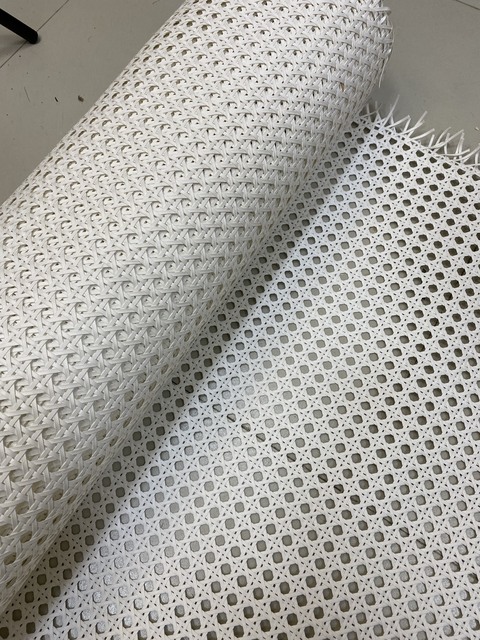

The appeal of cane webbing has never faded. Its lightweight openness, organic texture, and timeless woven aesthetic continue to dominate interior and hospitality design worldwide. Yet despite its popularity, natural cane presents clear performance limitations. Exposure to humidity, chlorine, salt air, or direct sunlight gradually weakens the organic fibers. In many cases, the material begins to sag, discolor, and deteriorate long before the furniture reaches the end of its intended service life. As modern projects push into more demanding environments - outdoor lounges, coastal resorts, wellness spaces, high-traffic commercial interiors—the industry has shifted toward more durable alternatives. PVC cane webbing and other forms of synthetic cane webbing have become indispensable materials for manufacturers and designers who require consistent performance without sacrificing visual warmth. This material preserves everything people love about traditional cane while solving the durability challenges that natural rattan cannot overcome.

PVC Cane Webbing Material Engineered for Today’s Environments

PVC Cane Webbing Performance That Outlasts Natural Rattan

The growing preference for synthetic cane webbing is not simply a trend—it is the result of proven material behavior in real-world conditions. PVC cane webbing withstands the kinds of challenges that consistently shorten the lifespan of natural cane. One of the most significant advantages is its complete resistance to water absorption. PVC does not swell, soften, or stretch when exposed to humidity or heavy rains. For outdoor lounges, resort pool areas, spas, and marine applications, this stability is crucial. Furniture maintains its tension, comfort, and visual appeal even through prolonged periods of moisture.

PVC Cane Webbing: Design Flexibility and Aesthetic Realism

Advanced extrusion technology has allowed synthetic cane webbing to evolve far beyond its early plastic-like appearance. Today’s PVC cane webbing can replicate the subtle fibers, tonal variation, and depth of natural rattan with impressive accuracy. At a normal viewing distance, most users cannot distinguish synthetic from natural.

Where PVC Cane Webbing Performs Best?

PVC and PE cane webbing excel in challenging environments that demand both durability and design appeal.

Things To Keep In Mind When Buying PVC Cane Webbing

Contact

VILATA COMPANY LIMITED- Address: Office 02, Pearl Plaza Building, 561A Dien Bien Phu, Ward 25, Binh Thanh District, Ho Chi Minh City, Vietnam

- Website: rattanvn.com

- Email: min.vilata@gmail.com

- Phone: +84.394.090.698

- Facebook: (1) Facebook