The global furniture industry highly values sustainable resources. Rattan material stands out as an exceptional choice. It provides unique strength and unmatched flexibility. Rattan is not a tree; it belongs to the palm family. It grows as a vigorous climbing vine in tropical forests. This botanical classification is essential to understand. It is distinctly different from materials like bamboo, which is a hollow grass. Rattan raw material offers a solid core structure. This feature contributes to its superior load-bearing capacity. Its popularity spans centuries of design history. Rattan continues to drive modern, eco-conscious interior trends today. The material delivers both aesthetic appeal and environmental responsibility.

Rattan Anatomy: Pole, Core and Skin

The rattan vine provides a highly versatile source of rattan material. Manufacturers utilize three distinct parts of the pole. Each part serves a unique purpose in furniture construction. Understanding this anatomy is key to specialized procurement.

The Pole: Primary Structural Component

The full, unprocessed stalk is called the pole. This rattan material pole is the primary structural component. Artisans bend it easily when heated by steam. The pole forms the load-bearing frames of chairs and sofas. Its solid nature prevents the risk of splitting during construction.

The Core: Inner Wicker Element

The spongy, porous inner pith is known as the core. Workers strip the glossy outer skin to expose this part. The core is often cut into thin, circular strips. These strips are the fundamental element of wickerwork. They create solid, decorative infill for furniture panels.

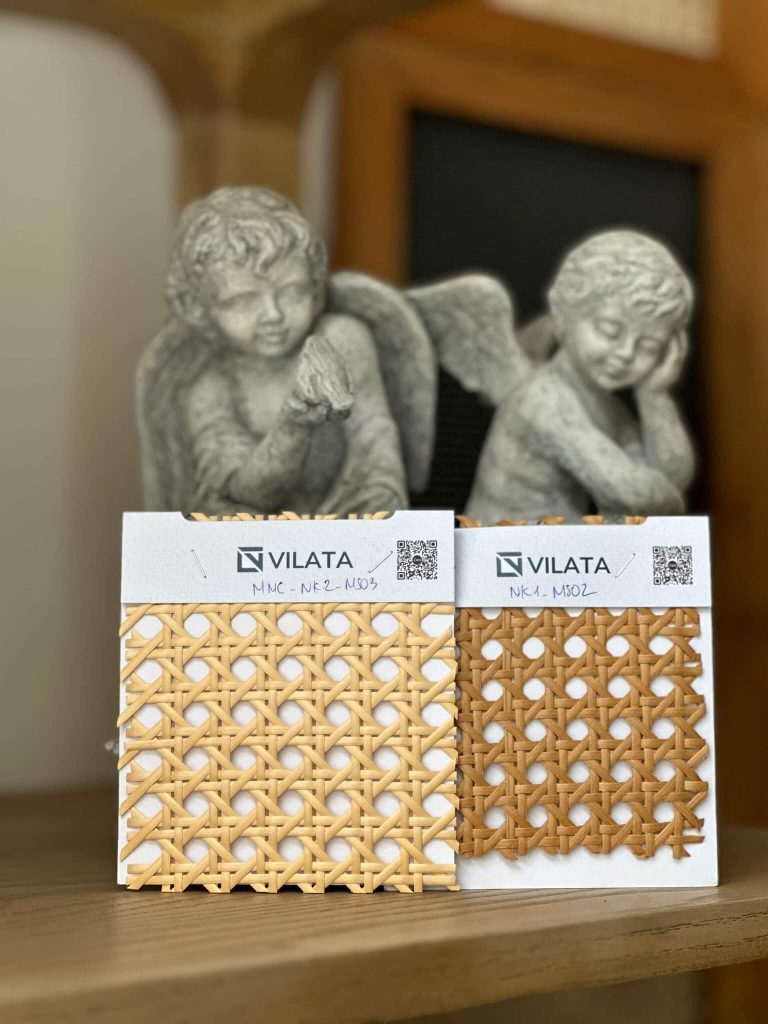

The Skin (Cane): Finishing and Webbing

The third component is the skin, or cane. This is the tough, outer bark of the rattan pole. Workers peel the skin into thin, strong strands. This glossy surface is used for fine binding and wrapping. Most importantly, it is the exclusive source for cane webbing. This webbing is prized for its elegance and durability.

Key Varieties and Sourcing

Hundreds of species of rattan exist under the calamus genus. Each species offers qualities in terms of strength and flexibility. They also vary significantly in color and texture.

Species Classification and Geographical Origin

Manau, Tawa, and Tohiti are among the most popular commercial varieties. These species originate primarily in Southeast Asia. Countries like Indonesia, the Philippines, and Vietnam are key global sources. The growth habit of rattan supports sustainable forestry practices. It is a rapid-growing, root-climbing vine. Harvesting mature rattan does not kill the plant. It encourages forest regeneration and growth. This makes rattan raw material one of the world’s most ecologically sound furniture resources. It minimizes environmental impact during procurement.

Material Grading Systems

Buyers classify rattan material through strict grading systems. Factors like pole diameter are crucial for structural use. Straightness and uniformity are also assessed carefully. Consistency in color and texture determines the aesthetic grade. Proper grading ensures the material is suitable for high-end manufacturing processes. Quality control starts immediately upon harvesting the vines.

The Raw Material Processing Chain

Transforming the raw vine into usable rattan material for furniture requires several specialized steps. This rigorous process is vital for ensuring stability and longevity.

Selective Harvesting and Transport

The initial step involves careful harvesting. Workers selectively cut only the mature vines. This practice protects the younger growth and the forest ecosystem. Harvesters then transport the poles to local processing centers quickly.

Cleaning and Curing for Stability

Cleaning and curing follow immediately after harvesting. The poles undergo rigorous cleaning to remove dirt and surface material. Workers then treat the rattan to prevent pest infestation. They also boil the poles in a specialized oil solution. This curing step removes natural sap and moisture. It stabilizes the rattan raw material internally. The material is then dried, either in the sun or using commercial kilns. Proper drying prevents future cracking and warping.

Sizing and Component Segmentation

The final stage is sizing and splitting the material. Skilled laborers cut the cured poles into specific furniture lengths. Machines mechanically separate the outer skin (cane) from the inner core (wicker). Both components are then sized into standard widths. This segmentation prepares the different elements for weaving and construction. The controlled processing chain guarantees material excellence.

Rattan Material in Furniture Applications

The versatility of rattan material allows for diverse aesthetic applications. Every component of the pole is utilized effectively. This maximizes the value of the harvested resource.

Structural Framing with Whole Poles

The whole poles are utilized for structural framing. These poles form the durable, primary framework of the furniture. They provide stability for sofa frames and cabinet legs. The pole’s inherent flexibility allows for intricate bends and curves. This capability creates unique, flowing furniture silhouettes.

Woven Elements and Wickerwork

The core material is used for woven elements or wickerwork. This material is soaked to increase its pliability before weaving. Weavers use it to create solid, highly decorative infill. These panels are common in the sides and backs of rattan material for furniture pieces. It produces the distinct texture of classic wicker seating.

Cane Webbing for Doors and Paneling

The glossy skin is used primarily for cane webbing. Thin strips of the cane are machine-woven into elegant mesh sheets. Designers often use this mesh for cabinet and rattan material for wardrobe doors. The open weave adds a light, breathable aesthetic. This application is highly sought after in luxury interior design. The material provides sophisticated visual detail.

Comparison: Rattan vs. Bamboo

Rattan and bamboo are often confused due to their similar appearance. They both grow in tropical regions. However, they possess fundamental structural differences. These differences determine their respective applications in furniture manufacturing.

Solid vs. Hollow Structure

Rattan is anatomically solid throughout its length. This solid structure provides exceptional strength and durability. Bamboo is anatomically hollow with internal nodes. This internal emptiness makes bamboo far less suitable for structural framing. It can easily split or buckle under heavy, concentrated load.

Flexibility and Strength

Rattan offers superior flexibility and bending capacity. Workers can bend the solid poles into complex curves using heat. Bamboo is stiff and much less pliable. It tends to split rather than bend when heat is applied. This limits bamboo’s use to straight or near-straight architectural elements. Rattan material provides greater tensile strength for structural pieces. This strength allows it to serve as the core framework of seating. Bamboo is better suited for decorative paneling and flooring. Manufacturers choose rattan for its unmatched structural integrity.

Sustainable Procurement: Ensuring Ethical and High-Quality Rattan Sourcing

Ethical sourcing is a major priority for modern global buyers. Rattan raw material is generally a sustainable choice. However, ethical harvesting practices must still be enforced.

Ethical Harvesting and Environmental Responsibility

Selective cutting supports continuous forest regeneration. Responsible suppliers prioritize this long-term environmental view. Quality control is paramount in the procurement process. Buyers must check for consistent diameter and straightness in the poles. They must also check for any signs of pest infestation.

Quality Control and Supply Chain Logistics

Proper curing and drying are essential for structural stability. Purchasing from certified suppliers guarantees material uniformity. The global supply chain for rattan material for furniture presents challenges. These include logistics, shipping regulations, and import documentation. Working directly with an experienced exporter simplifies this process. Direct sourcing ensures higher quality control from the forest stage onward. It also provides better traceability and transparent pricing. This approach safeguards the investment in high-grade rattan material. It secures a reliable, high-quality material flow for furniture manufacturing.

Contact Information

VILATA COMPANY LIMITED

Office 02, Pearl Plaza Building 561A Dien Bien Phu, Ward 25, Binh Thanh District Ho Chi Minh City, Vietnam

Website: rattanvn.com

Email: min.vilata@gmail.com

Phone: +84 394 090 698

Facebook: (1) Facebook