The modern furniture industry relies on standardized components. Cane webbing roll is a vital manufacturing material. It provides an ideal combination of traditional aesthetics and practical function. This specialized product is derived from the outer skin of the rattan vine. Skilled workers process the raw material carefully. The result is a uniformly woven cane webbing mesh. This mesh serves a dual role in interior design. It enhances visual appeal while ensuring adequate ventilation. Manufacturers purchase it globally for use in mass production. This guide details the essential product specifications for buyers. Understanding these formats ensures efficient procurement practices.

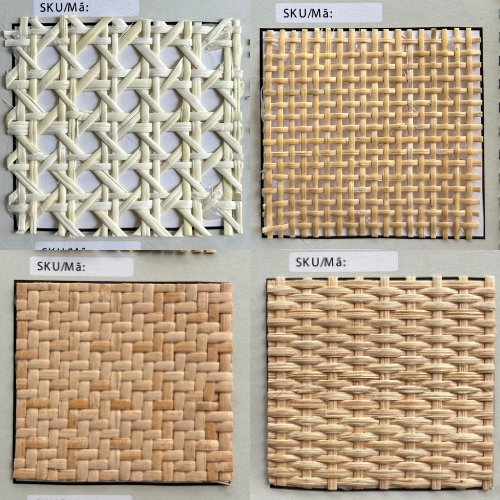

Classification by Weave Pattern: The Primary Types

Weave pattern classification is the first step for any buyer. The pattern significantly influences both the material’s final strength and its decorative aesthetic. Different patterns suit different furniture applications. Choosing the correct weave prevents later structural or visual issues.

Hexagonal Weave

The hexagonal weave is the most common style. Many designers refer to it as the standard “cannage” pattern. This pattern is easily recognizable worldwide. It features open, repeated hexagonal holes. The design makes the webbing exceptionally lightweight. It allows for high air permeability in cabinets. We recommend this style for purely decorative applications. These applications include cabinet doors and small accent cane webbing panel inserts. The structure is inherently lighter and more delicate than other types.

Square Weave

The square weave offers a visibly tighter structure. This density results in a more solid material. It provides superior strength compared to the hexagonal type. The tighter weave increases material consumption slightly. Manufacturers often use square weave in seating applications. These areas include the seat base or backrest infill. It typically requires robust reinforcement underneath. The solid backing ensures long-term structural integrity. This pattern is essential when moderate load-bearing is necessary.

Custom Decorative Patterns

Specialty weaves are also available for large orders. These custom designs include patterns like Parisian or radio weave. They offer unique textures and visual variety. Such decorative options require bespoke production runs. They are usually reserved for exclusive or high-end projects. Buyers should confirm minimum order quantities early. Custom patterns allow for unique brand differentiation.

Commercial Product Formats: From Roll to Panel

Procurement specialists must navigate various commercial formats. The format chosen impacts production efficiency and cost per unit. Cane webbing roll is the primary unit for bulk manufacturing.

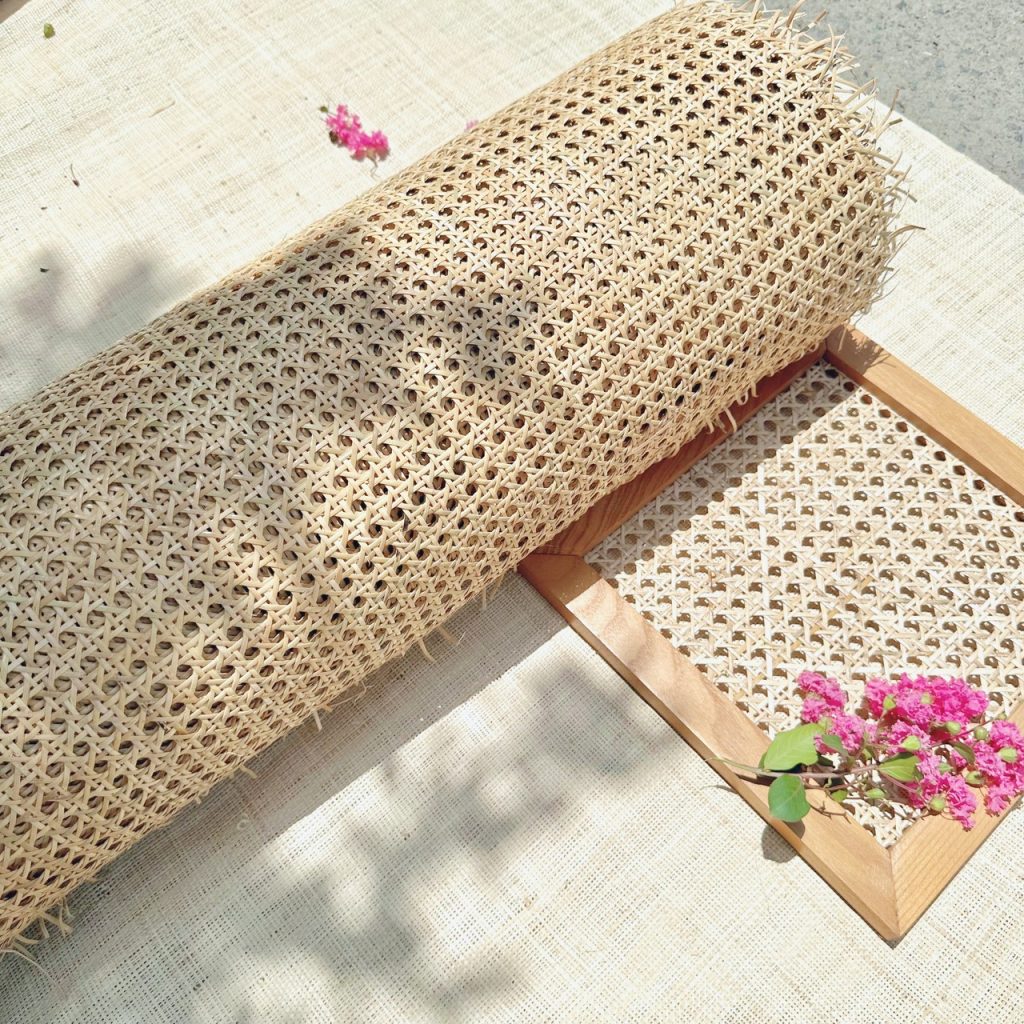

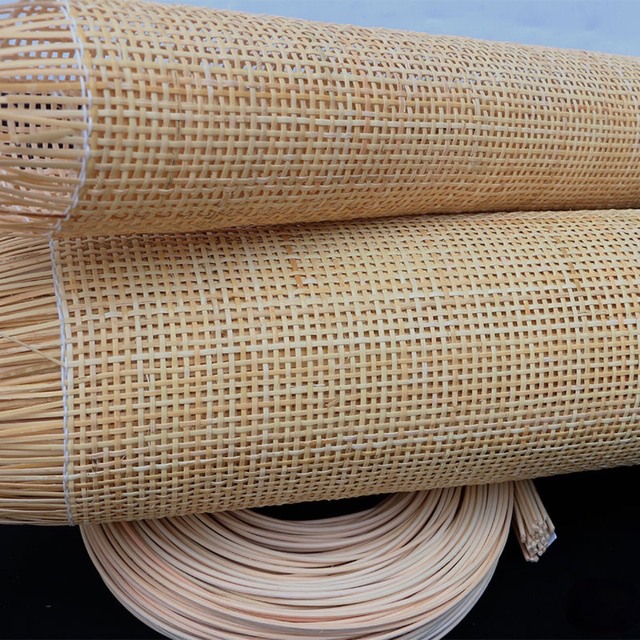

Cane Webbing Roll

The cane webbing roll represents the standard industrial purchasing unit. Manufacturers buy it in bulk for high-volume production lines. Standard roll lengths are typically 15 meters or 50 feet. Common widths are standardized to 45 cm, 60 cm, and 90 cm. This bulk format minimizes waste when cutting components. It is the most cost-effective way to source large quantities. We highly recommend using the roll format for efficiency.

Cane Webbing Sheet and Fabric

The terms cane webbing sheet or cane webbing fabric refer to smaller, pre-cut pieces. Suppliers usually offer these formats to smaller workshops. They also serve customers needing repairs or samples. These smaller sheets are ideal for limited-scope projects. They carry a higher unit cost compared to the bulk roll price. Buyers should use this format strictly for small-batch requirements.

Pre-Framed Cane Panel

The cane webbing panel is a ready-to-install component. Workers insert the webbing material into a wooden or aluminum frame beforehand. This eliminates the need for specialized framing labor in the factory. The benefit is a significant reduction in onsite assembly time. This product is popular for simplified production logistics. It is often used for quick installation in modular furniture systems. This format is typically the most expensive option.

Technical Specifications: Key Metrics for Buyers

Quality assurance hinges on precise technical metrics. Buyers must confirm these details before finalizing any large order. Consistency in specifications is crucial for seamless production.

Strand Width and Mesh Aperture

Dimensional data is a critical metric for quality control. Strand width refers to the thickness of the individual cane strips. A common width is approximately 1.8 mm. Mesh aperture defines the size of the hole opening. A typical size is a 1/2-inch aperture. These metrics directly influence the final product’s strength. They also affect the transparency of the cane webbing mesh. Consistent dimensional data prevents aesthetic discrepancies across units.

Material Grade and Finish

Raw cane skin is graded based on its quality. Grades range from A (premium) to C (commercial). Grade A material ensures maximum smoothness and minimal blemishes. It also guarantees highly uniform coloring. Suppliers should provide certifications confirming the material grade. Uniform color is essential for high-end furniture aesthetics. The finish, often a clear lacquer, protects the material surface.

Moisture Content and Curing

Controlling moisture content is vital for dimensional stability. Proper oil curing and kiln drying stabilize the material fibers. The required moisture content should be low and stable. We recommend a range of 8 to 12 percent. This stability prevents the webbing from shrinking or expanding. Instability can cause distortion or looseness after installation. This technical metric prevents costly post-installation failures.

Application Matching and Installation Guidance

Matching the webbing type to the intended use optimizes the final product. Different patterns and formats suit distinct furniture components. This selection process requires technical insight into material performance.

Cabinetry and Doors (Wardrobes, Sideboards)

We recommend the hexagonal cane webbing mesh for cabinetry. This application prioritizes aesthetic lightness and ventilation. The mesh promotes air flow within the cabinet interiors. This breathability is important for storage units. The webbing typically acts as a decorative infill within a solid frame. It creates an appealing visual texture for the cane webbing panel.

Seating and Structural Elements

The square weave is the better option for seating surfaces. Its higher material density provides better initial support. However, it requires a robust support structure underneath. Manufacturers often use foam or fabric backing for comfort. The structural frame itself must manage the main load. The webbing acts as a durable, textural cover.

Acoustic and Divider Screens

The material also functions well in screen applications. Designers use it for room dividers or architectural screens. The cane webbing sheet adds texture without blocking light entirely. It allows light to diffuse softly throughout the space. The visual effect maintains an open and airy feel. It contributes to sophisticated interior segmentation.

Sourcing, Customization, and Ordering

Efficient sourcing requires strategic planning and quality control checks. Addressing procurement details early streamlines the entire supply chain.

Minimizing Waste

Waste minimization is crucial for cost control. Buyers must calculate the required cutting width accurately. This calculation should use the component size as the base metric. Ordering the most suitable cane webbing roll width reduces material offcuts. Smart ordering minimizes overall production costs.

Quality Sourcing and Traceability

We emphasize buying direct from reputable manufacturers. This practice ensures consistent batch quality across large orders. It also allows for full traceability of the cane webbing fabric source. Traceability confirms ethical and sustainable harvesting practices. Reliable sourcing secures a consistent, high-quality material supply.

Custom Finishes and Branding

Customization options enhance brand identity. Manufacturers can offer pre-dying services for unique color requirements. They can also apply clear lacquer finishes before shipping. Custom packaging and branding are also available for major partners. These services support a unique market presentation for your final products.

Conclusion: Partnership and Procurement

For buyers committed to superior quality and reliable supply, VILATA COMPANY LIMITED is the definitive sourcing partner. We provide the highest-grade cane webbing roll products. Our commitment to technical specifications and ethical sourcing ensures your projects succeed. Contact our team to discuss custom orders and technical certifications.

Contact Information

VILATA COMPANY LIMITED

Office 02, Pearl Plaza Building 561A Dien Bien Phu, Ward 25, Binh Thanh District Ho Chi Minh City, Vietnam

Website: rattanvn.com

Email: min.vilata@gmail.com

Phone: +84 394 090 698

Facebook: (1) Facebook